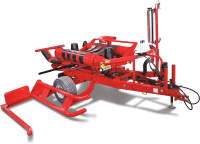

A1230FD

Resource center

2026

- Anderson_ANG_Spread (453 MB)

2025

- ANG brochure 2024-2025 (113 MB)

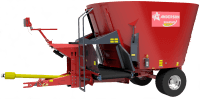

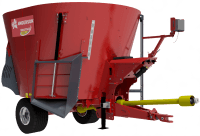

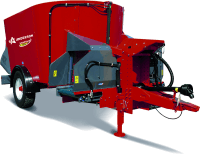

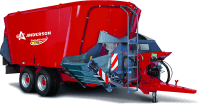

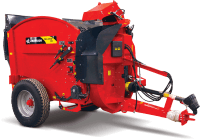

The pull type A1230 triple auger mixer (conveyor discharge) becomeS a perfect solution with their distribution conveyor ideal for fibrous rations. The cross conveyor ensures even and prompt distribution to the left or right regardless of the prepared ration. Anderson knows it is with high quality raw materials that we manage to achieve nutritional goals and high production. The mixing rate should be adapted to avoid any risk of overheating and grinding that could lead to diminished efficiency of the TMR.

Features and options

- 1.

Capacity 1 236 pi3 à 1 575 pi3.

- 2.

Reinforced tub fl oor provides longevity of the tub and also to the load cells by equalizing the weight uniformly.

- 3.

TRI-CUT™, auger with 2-position adjustable and reversible knives (10 standard) and 2 sweeping dispensers ensuring a 30% faster and more consistent discharge.

- 4.

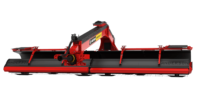

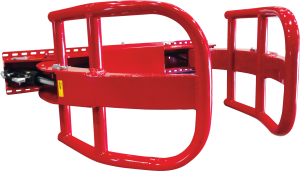

Discharge options: front conveyor

- 5.

Carbide treated self-sharpening tungsten knives.

- 6.

Industry’s fi rst hydraulic TRUE-CUT™ restrictor blades allows the operator to engage and disengage during the mixing process preventing all risks of overprocessing feed.

- 7.

The DG500 indicator is a universal, programmable weighing indicator for recipes, dispensing and data storage. It guarantees an extremely precise weighing thanks to the protected load cells and strategically located under the tank. Compatible with the DTM suite.

- 8.

6-point scale system.

- 9.

Rolled side walls (not bent) for better fl ow of material, avoiding restriction around auger and naturally increased sturdiness.

- 10.

SMART CONTROL remote control (optional) provides you full wireless control to: customize weighing system and recipe, hydraulics, speed of belt etc.

- 11.

Standard 2 speed gearbox.

| Capacity | |

|---|---|

| Capacity (no capacity extension) | 1230 ft3 (34.9 m3) |

| 6 in capacity extension | 1344 ft3 (38.1 m3) |

| 12 in capacity extension | 1458 ft3 (41.3 m3) |

| 18 in capacity extension | 1572 ft3 (44.5 m3) |

| Number of Auger | 3 |

| Dimensions | |

|---|---|

| Length (A) | 43in(88888cm)0 in (10.91 m) |

| Height (B) no extension | 117 in (2.97 m) |

| 6 in capacity extension | 123 in (3.12 m) |

| 12 in capacity extension | 129 in (3.28 m) |

| 18 in capacity extension | 135 in (3.43in(88888cm) m) |

| Hay retention ring (additionnal height) | 0 in / 3,5 in |

| Width (C) | |

| Without incline conveyor | 112 in (2.84 m) |

| With incline conveyor (retracted) | 124 in (3.15 m) |

| Incline conveyor operating angle (degrees) | 26 @39 |

| Outside width of the wheels | 101 in (2.57 m) |

| Lateral distance to discharge point (D) | |

| Incline conveyor chain / belt 3 ft at min.26 angle /max 40 | 23-21in at 26º / 21-18in at 40º |

| Incline conveyor chain / belt 4 ft at min. 26 angle /max 40 | 48-50in at 26º / 57-57in at 40º |

| Incline conveyor chain / belt 5 ft at min. 26 angle /max 40 | 55-57in at 26º / 68-68in at 40º |

| Incline conveyor chain / belt 6 ft at min. 26 angle /max 40 | 59-61in at 26º / 74-74in at 40º |

| Incline conveyor chain / belt 7 ft at min. 26 angle /max 40 | 66-68in at 26º / 84-84in at 40º |

| Incline conveyor chain / belt 8 ft at min. 26 angle /max 40 | 70-72in at 26º / 90-90in at 40º |

| Discharge height (E) | |

| Incline conveyor chain / belt 3 ft at min. 26 angle /max 40 | 44-46in at 26º / 51-51in at 40º |

| Floor ST (E1) / Conveyor FD (E2) to ground | 35 in (0.88 m) |

| Specifications | |

|---|---|

| PTO shaft - Standard specification | 1000 RPM 1" 3/4 Z20 |

| PTO shaft - Option specification | 1000 RPM 1" 3/8 Z21 |

| 2 speed Gear Box | Optional |

| 2 Speed Gear Box and ratio | A613R 2spd, A614R, 1;1.8;3.2@3spd |

| Minimum PTO HP Requirement - Low Speed | 145 |

| Minimum PTO HP Requirement - High Speed | 210 |

| Auger RPM – Low Speed | 18 RPM / 10 RPM |

| Auger RPM – Standard High speed | 33 RPM |

| Standard planetary model and ratio configuration | 3002 @30.24 |

| Optionnal Planetary | N/A |

| Floor Thickness (AR235 grade or equivalent) | 3/4 in |

| Sidewall Thickness (AR235 grade or equivalent) | 1/4 in |

| Flighting Thickness (AR235 grade or equivalent) | 5/8 in |

| Standard knives per auger | 8 / 12 optional |

| Driveline security | Shear clutch |

| Hydraulic flow requirement | 10-15 US gal/ min 37-56 L/ min |

| Hydraulic pressure | 160-200 bars (2300-2900 psi) |

| Load cell | 6 |

| Scale system | DG500 (standard) |

| Machine Weight (empty) - STD configuration | 28 991 lb (13148 kg) |

| Utility load capacity | 35 670 lb (16177 kg) |

| Axle - Standard specifications | Tandem |

| Axle - Optional specifications | Tridem / self steering axle |

| Wheels - Standard specifications | 275/70R22.5 (DOUBLE) |

Do you like this product?

Do you want to offer it to your customers?

Want to become the distributor of your area?