A520FD

Resource center

2026

- Anderson_ANG_Spread (453 MB)

2025

- ANG brochure 2024-2025 (113 MB)

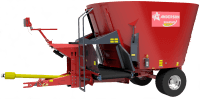

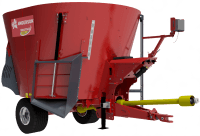

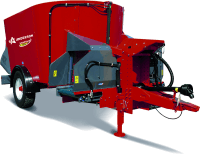

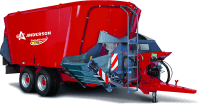

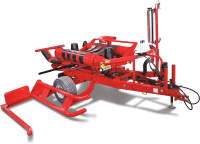

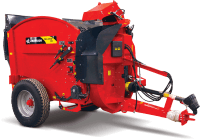

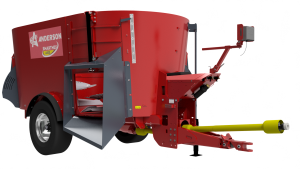

The Anderson pull type A520 twin auger mixer (conveyor discharge) has the ability to mix the widest variety of ingredients. Process large amount of hay, even complete square and round bales of baleage. Available with several discharge options. Whether your rations are designed to increase milk production of dairy cows or minimize variation in feed for each group you feed, vertical mixer will help optimize the dry matter and nutrient intake of your herd.

Features and options

- 1.

Capacity 520 pi3 à 666 pi3.

- 2.

Reinforced tub fl oor provides longevity of the tub and also to the load cells by equalizing the weight uniformly.

- 3.

TRI-CUT™, auger with 2-position adjustable and reversible knives (10 standard) and 2 sweeping dispensers ensuring a 30% faster and more consistent discharge.

- 4.

Discharge options: Side trap or front conveyor.

- 5.

Carbide treated self-sharpening tungsten knives.

- 6.

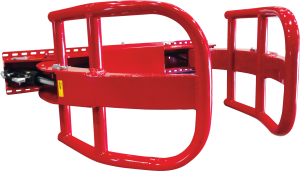

Industry’s fi rst hydraulic TRUE-CUT™ restrictor blades allows the operator to engage and disengage during the mixing process preventing all risks of overprocessing feed.

- 7.

The DG500 indicator is a universal, programmable weighing indicator for recipes, dispensing and data storage. It guarantees an extremely precise weighing thanks to the protected load cells and strategically located under the tank. Compatible with the DTM suite.

- 8.

3-point scale system.

- 9.

Rolled side walls (not bent) for better fl ow of material, avoiding restriction around auger and naturally increased sturdiness.

- 10.

SMART CONTROL remote control (optional) provides you full wireless control to: customize weighing system and recipe, hydraulics, speed of belt etc.

- 11.

Optional 2 speed gearbox.

| Capacity | |

|---|---|

| Capacity (no capacity extension) | 520 ft3 (14.7 m3) |

| 6 in capacity extension | 574 ft3 (16.3 m3) |

| 12 in capacity extension | 628 ft3 (17.8 m3) |

| 18 in capacity extension | 682in(208cm) ft3 (19.3 m3) |

| Number of Auger | 2 |

| Dimensions | |

|---|---|

| Length (A) | 270 in (6.86 m) |

| Height (B) no extension | 102 in (2.59in(150cm) m) |

| 6 in capacity extension | 108 in (2.74 m) |

| 12 in capacity extension | 114 in (2.9 m) |

| 18 in capacity extension | 120 in (3.05 m) |

| Hay retention ring (additionnal height) | 0 in / 3,5 in |

| Width (C) | |

| Without incline conveyor | 101 in (2.57 m) |

| With incline conveyor (retracted) | 117 in (2.97 m) |

| Incline conveyor operating angle (degrees) | 26 @39 degrees |

| Outside width of the wheels | 99 in (2.51 m) |

| Lateral distance to discharge point (D) | |

| Incline conveyor chain / belt 3 ft at min.26 angle /max 40 | 30-28in at 26º / 28-25in at 40º |

| Incline conveyor chain / belt 4 ft at min. 26 angle /max 40 | 37-39in at 26º / 46-46in at 40º |

| Incline conveyor chain / belt 5 ft at min. 26 angle /max 40 | 44-46in at 26º / 57-57in at 40º |

| Incline conveyor chain / belt 6 ft at min. 26 angle /max 40 | 48-50in at 26º / 63-63in at 40º |

| Incline conveyor chain / belt 7 ft at min. 26 angle /max 40 | 55-57in at 26º / 73-73in at 40º |

| Incline conveyor chain / belt 8 ft at min. 26 angle /max 40 | 59-61in at 26º / 80-80in at 40º |

| Discharge height (E) | |

| Incline conveyor chain / belt 3 ft at min. 26 angle /max 40 | 33-35in at 26º / 40-40in at 40º |

| Floor ST (E1) / Conveyor FD (E2) to ground | 24 in (0.61 m) |

| Specifications | |

|---|---|

| PTO shaft - Standard specification | 540 RPM 1" 3/8 Z6 |

| PTO shaft - Option specification | 1000 RP m 1" 3/8 Z21 |

| 2 speed Gear Box | Optional |

| 2 Speed Gear Box and ratio | C3A-R, 1;1,5 54in(888cm)0 RPM C3A-R, 1,8;2,7 1000 RPM |

| Minimum PTO HP Requirement - Low Speed | 80 |

| Minimum PTO HP Requirement - High Speed | 120 |

| Auger RPM – Low Speed | 27 RPM |

| Auger RPM – Standard High speed | 41 RPM |

| Standard planetary model and ratio configuration | 1602 @13.4 |

| Optionnal Planetary | N/A |

| Floor Thickness (AR235 grade or equivalent) | 5/8 in |

| Sidewall Thickness (AR235 grade or equivalent) | 1/4 in |

| Flighting Thickness (AR235 grade or equivalent) | 5/8 in |

| Standard knives per auger | 6 / 10 optional |

| Driveline security | Shear bolt |

| Hydraulic flow requirement | 10-15 US gal/ m in 37-56 L/ m in |

| Hydraulic pressure | 160-200 bar (2300-2900 psi) |

| Load cell | 3 |

| Scale system | DG500 (standard) |

| Machine Weight (empty) - STD configuration | 13 100 lb (59in(150cm)41 kg) |

| Utility load capacity | 15 080 lb (6839 kg) |

| Axle - Standard specifications | Single |

| Axle - Optional specifications | N/A |

| Wheels - Standard specifications | 385/65R22.5-20 |

Do you like this product?

Do you want to offer it to your customers?

Want to become the distributor of your area?