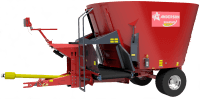

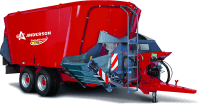

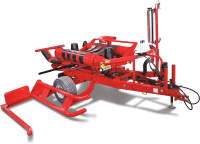

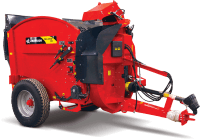

Ellipse 660

Why buy the Ellipse 660?

Increased wrapping cycle time compared with turn-table individual wrapper

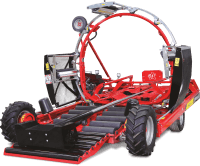

To speed up bale wrapping using conventional single bale wrapping, you need to increase the wrapping table’s rotation speed. But this can be problematic when faced with large, oddly shaped bales like cones or sags, as you must keep the table’s RPM under 20-23 to avoid ejecting the bales. It is not an issue with the Ellipse as it provides a wrapping cycle time of less than a minute (loading, wrapping, unloading).

Not limited in bale size

The Ellipse is the only machine designed to perform well at wrapping bales 5 feet wide by 5’6 inches in diameter.

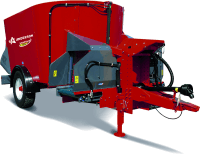

Rear bale guide

While unloading the bale, the rear wrapping guide descends to softly set the wrapped bale on the ground

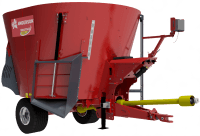

Fastest wrapping process

The ELLIPSE660 wrapping cycle time is less than a minute (loading, wrapping, unloading).As the lifting arm moves the bale onto the wrapping platform, the front roller lowers to reduce the vertical distance the bale travels to reach the wrapping area. This setup ensures a smooth and efficient transition, reducing stress on the equipment. Furthermore, even if the wrapping process remains unfinished, you have the flexibility to transport a bale using the loading arm while in progress.

Bale guide

The bale guides adjusts to the bale’s size, ensuring consistent plastic application to the bale for precise and uniform wrapping every time. The Ellipse wrapper’s bale guides effortlessly covers bales sized up to 5,5 feet .

Robust Lifting arm

The sturdy lifting arm mechanism can transport one bale while wrapping another, resulting in increased productivity.

Cut & Hold System

Once the wrapping cycle ends, the hydraulic-powered cut & Hold system slices the film and securely maintains it in place, preparing for the next bale to be wrapped.

Plastic film watch

A film watch detection system is there to constantly observes the plastic as it exits the rolls. In the event of a plastic rupture or failure of any sort, the machine will send an alert to the operator through the control panel.

Additional film storage

The Ellipse has the capacity to transport 6 film rolls: 2 rolls within the dispensers and an extra 4 rolls stored in the film storage section.

Interested in the Ellipse 660?

Ellipse 660

Bales

| Round bale diameter | Up to 5’6” (1.65m) |

| Round bale length | Up to 5 ft (1.5 m) |

| Square bale | N/A |

| Wrapping speed | Up to 75 bales/h |

| Wrapping process | Automatic |

| Mode | Pulled behind |

Specification

| Aluminum film stretcher | 2 x 30" |

| Engine | N/A |

| Bale dumper | 2 position series ball flipper for bales of 4 and 5 feet |

| Bale guides rollers | Standard |

| Leveling system | N/A |

| Road lights | For tractor |

| Night Work lights | Standard |

| Tires | 15.0/55-17 14PRTL |

| High floatation Tires | Standard |

| Plastic cut & hold system | Hydraulic |

| Self-loading arm | Standard |

| Electronic bale counter | Standard |

| Tractor Minimum Hydraulic Flow | 15 gpm (57 liters/min) |

| Tractor Minimum Hydraulic Pressure | 2500 psi (172 bar) |

| Hydraulic connections | Option 1: Load sensing and pump output + 1 hydraulic output + free returnnOption 2: 2 hydraulic outputs + free return" |

Dimensions

| Overall width – B | 23 ft 1 in (7.04 m) |

| Overall height – C | 9 ft 10 in (2.97 m) |

| Overall length – A | 10 ft 7 in (3.22 m) |

| Overall weight | 5780 lbs |

The Anderson Ellipse single bale wrapper represents a cutting-edge round bale wrapper, designed to ensure a uniform and reliable wrap application while enhancing hay preservation and maintaining great quality. Unlike other machines of its type it is designed for bales ranging in length from 4 to 5 feet, with a diameter spanning from 4 feet to 5 feet and 6 inches.

Unlike a turntable design, the Ellipse660 stands out for its superior bale stability. By making the bale rotate only on its edges, we’ve eliminated the problem of bales with irregular shapes or working on uneven terrain. This prevents bales from being ejected from the wrapping table, reducing safety risks and potential equipment damage.